Man-Powered Flight

I remember as a kid thinking that if I could pedal my bicycle fast enough, it could fly. Imagine taking that childhood dream and turning it into reality. That’s exactly what a group of determined visionaries set out to do, and their story is nothing short of inspiring.

From the mythical wings of Icarus to the sketches of Leonardo da Vinci, humanity has long been captivated by the idea of man-powered flight. But could we truly lift ourselves into the sky with nothing more than our own strength? By the 1930s, two experimental airplanes had hinted at the possibility, but it wasn’t until 1959—when a British industrialist dangled the tantalizing promise of a £5,000 prize—that the dream truly took flight.

In this story, we’ll dive into the challenges and triumphs of three British teams, each striving to design and build an aircraft powered solely by human effort. From university students crafting lightweight wooden wings in their spare time to seasoned engineers pushing the boundaries of innovation, the race to achieve man-powered flight became a thrilling blend of ingenuity, perseverance, and a touch of madness.

Will their designs soar gracefully or crash under the weight of ambition? Join me as we explore the fascinating journey of those who dared to pedal their way into the history books.

Originally published as “Man-Powered Flight” by Daryl May in the June 1963 issue of Flying magazine, this tale captures the audacious spirit of innovation that reminds us all to dream big—and maybe, just maybe, fly higher.

Man-powered Flight by Daryl May, published in the June 1963 issue of Flying magazine.

By aero-engine standards, the human body is simply a bag of bones. It is complex, bulky, inefficient and extraordinarily heavy for the power it produces. And it suffers from special short- comings of its own—such as fatigue and laziness. You would not think any airplane designer would succeed with an engine like this. And, until just recently, none ever did.

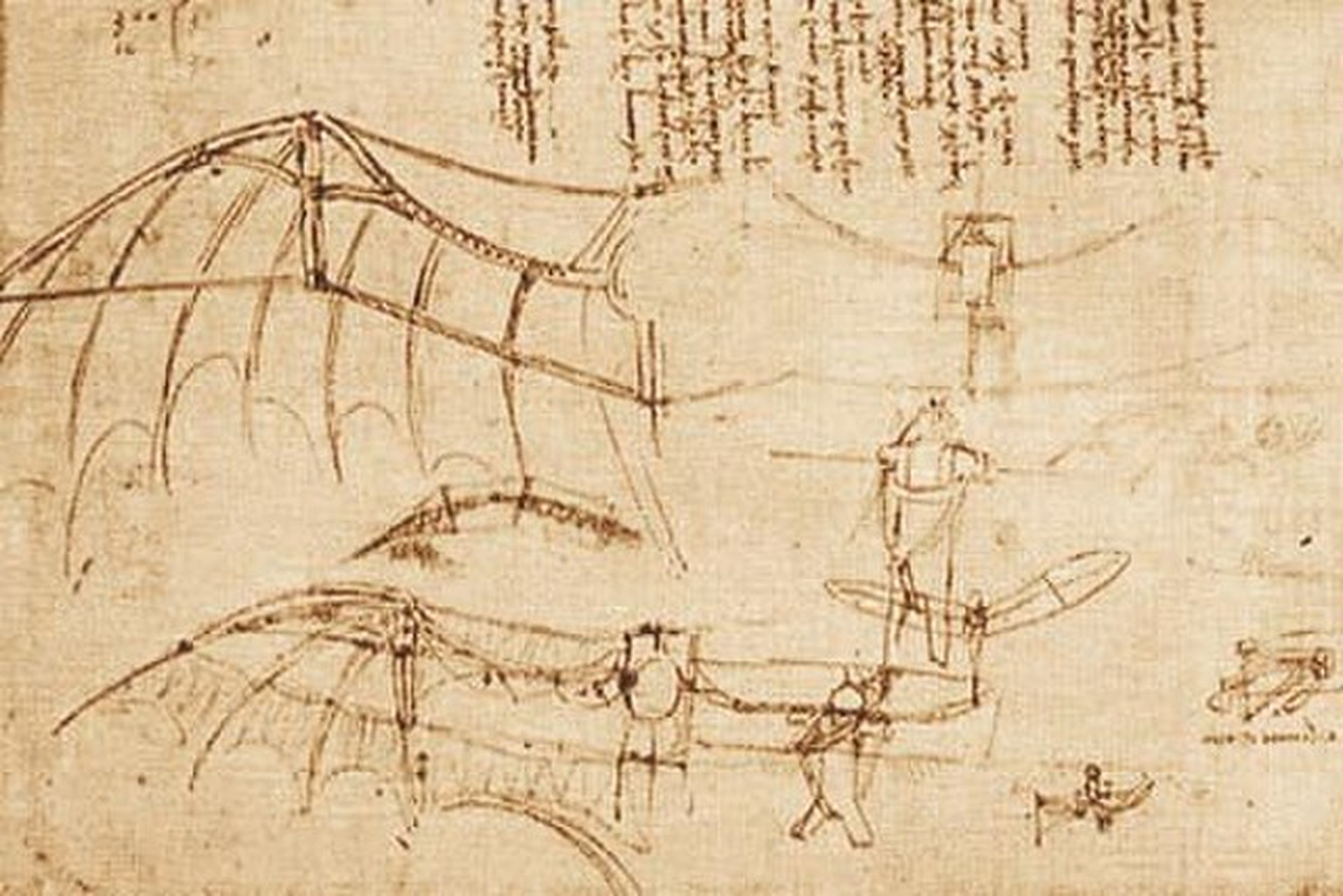

Man-powered flight has always been one of man’s more utopian dreams, but the realization of the dream has been along a far from utopian path. It is said that in 1400 B.C. Icarus tried the wax-and-feather approach, but high-temperature conditions modified the design in fight and the pilot was lost. Leonardo da Vinci had some very artistic designs, which, fortunately for the test pilot, were never built. And Otto Lilienthal, birdman of the last century, killed himself in glider tests. By 1930, after a thousand stories of failure, people were inclined to agree that man-powered flight was strictly for the birds.

Then in 1935-37 came two airplanes which proved the possibility of man-powered fight. Both were catapult-launched and it is not certain that either ever took off under the power of its pilot alone. But, catapult-launched, the German Haessler-Villinger machine flew 700 yards in a straight line and the Italian Bossi-Bonomi about 1,000 yards over a near-rectangular course. Man-powered fight was in the books and the achievement of unassisted takeoff followed by long-distance flight seemed only a matter of development.

Here the story would have ended were it not for a sudden and intense resurgence of interest shown by the British in the last few years. The Grand Ideal had always been present, but the spur had not been until November 1959 when industrialist Henry Kremer offered €5,000 ($14,000) to the team that first constructed an aircraft which, without the use of lighter-than-air gases or devices for storing energy, took off under the power of its crew alone and flew a figure-eight course around two posts a half-mile apart, beginning and finishing at a height of over 10 feet. The course is, in effect, a means of proving the ability to take off, turn and fly a reasonable distance. Additionally, Kremer stipulated that the designer, entrant, pilot and land of construction and flight must be British.

In June 1960, soon after the announcement of the Kremer competition, the Royal Aeronautical Society’s recently-formed Man Powered Aircraft Group expressed its willingness to provide financial assistance to teams submitting promising design studies. After evaluation of many submissions, including some rather hopeful flap-wing and helicopter projects, the Society made grants to help build three airplanes:

- SUMPA (Southampton University Man-Powered Air-craft), a one-place machine designed and built by students in the laboratories of the Department of Aeronautics and Astronautics of this British university. A grant of €1,500 ($4,200).

- Puffin, another one-place airplane, designed and built by the Hatfield Man Powered Aircraft Club, assisted in every way by de Havilland at Hatfield. Brain behind the scheme is John Mimpenny, de Havilland’s Assistant Chief Designer. Grant is also €1,500.

- Southend Man Powered Aircraft Club’s courageous two-place design by a group of engineering workers with no help beyond a grant of £750 ($2,100).

One basic equation related the varying approaches of the three teams—the power of the human body. Man may indeed be a bag of bones, but information is remarkably scant on just how inefficient he is. All three teams did considerable research on the problem and stimulated work by others in this field. It was found that for a short period of perhaps three minutes, a man can make use of energy stored in his muscles, but that even a champion athlete could sustain only about .6 hp.

When you realize that an efficient modern sailplane needs about four hp for straight and level fight, it is obvious that very severe problems needed overcoming. The secret of success is clearly to design a lightweight structure, strong enough to carry the loads but not too strong. Reinforcement by way of over-stressing might make for higher structural strength but it brings a weight penalty that has to be avoided. Although each of the three aircraft has a wing span more than twice as great as a Cessna 310’s or an Aztec’s, none of them weights more than 140 pounds empty—one-twentieth as much.

The Southampton machine was the first to fly.

Alan Lassiere, Anne Marsden and David Williams were all final-year undergraduates when they decided to lunch SUMPA.

The ribs and spars are made mainly from spruce and balsa; the ribs of girder construction and the spars multi-laminated using one of the five different glues used on the airplane. The wing is made in three sections joined by aluminum alloy fittings glued to the wood. Covering is by parachute nylon, doped silver to protect the structure from ultra-violet light. An aspect ratio of 21.3 shows how slender the wing is. With its span of 80 feet, the wing-loading is remarkably low—.90 pounds per square foot. The center section is 20 feet long and bolts directly to the upper part of the fuselage.

The outer sections, each 30 feet long, have a slight dihedral and carry the 20-foot-long ailerons. There are no flaps.

The pilot and power transmission system defined the shape of the fuselage. Either you have good visibility and too much frontal area, reasoned the designers, or bad visibility and low frontal area. And you have to find a position for the pilot so that he can pedal comfortably. Eventually they compromised and put the pilot in a semi reclining position, leaning backwards. He has a backrest which provides the reaction for his legs, leaving his arms free for controlling the airplane. He sees through a window in a vertical pylon which is the support for the pusher propeller mounted above and behind the wing.

Fuselage features spruce longerons; its four sides are built up on the flat just like a model airplane’s and assembled around a few frames. The cockpit is made of aluminum alloy tubing. At its front end is an eight-inch sprung nose-wheel: just behind the pilot is the main undercarriage in the form of a 27-inch bicycle wheel.

Transmission from the pilot’s pedals to the propeller needed special study. Because the propeller was most efficient around 20 mph and most inefficient at lower speeds, it was necessary to power the airplane up to takeoff speed through the bicycle wheel. The transmission, therefore, went from the pedals to the wheel, then up to the propeller.

Pedals are designed to turn 90 rpm, giving a propeller speed of 260 rpm.

Because the pilot needed his legs for pedaling, the rudder controls had to be incorporated into the hand-controls. Besides a normal forward-and-back movement for elevator and left-right movement for aileron, the control (a horizontal bar) can be swiveled about a vertical axis like a foot-operated rudder bar. Nylon-covered steel shark-fishing wire operates the control surfaces.

SUMPA was built in the evenings and weekends through 1961 and was taken to the big Lasham Gliding Centre by trailer in September. Would it work?

The question was no laughing matter by then because the project had progressed beyond the pocket-money stage to one where other people’s facilities and money had been freely used. Additionally, some of the team—most had by then graduated with B.Sc. degrees—were planning to submit for M.Sc. degrees on the basis of their research into man-powered flight.

The designers had calculated that to cover the figure-8 of the Kremer course they needed a pilot who could .55 hp for one minute on takeoff followed by .45 hp for another four minutes. But there was one big unknown; they were not sure how much help they would get from the ground effect, by flying less than 15 feet high and benefitting from the “lift-sandwich” between wing and ground. Pilot on the first fight was Derek Piggott, Chief Gliding Instructor of the biggest gliding center in the country.

They wheeled out SUMPA for initial taxi trials after waiting for a day that was absolutely still. Under each wing was a loop of wire to prevent it from touching the ground. The first trials were marked by four frustrating though not serious accidents. The cycle chain came off. The bicycle wheel got a puncture. Load on the pedal bent the aluminum frame which had to be straightened and strengthened. Then in a “high-speed” taxi run, the airplane swung off the runway, damaging the nose-wheel and front framework,

Finally, at 4:30 p.m. on 9 November 1961, Derek flew 50-70 yards at an altitude of about 5 feet.

Film of the early flight trials showed that the main-wheel was slipping repeatedly just before the airplane climbed away. This meant that the wheel had provided flying speed before the propeller was going fast enough to take over. The gear ratio was altered and flights on 24 and 25 November proved the trouble had been overcome. The airplane flew 30 seconds and 300 yards.

The test program of any revolutionary airplane brings to light many unexpected problems. There was little experience of fight at 20 mph and the lack of feel coupled with control friction made SUMPA difficult to fly. They tested various improvements by towing the machine behind a car.

Derek found difficulty in turning, despite the fact that up-aileron movement was twice as great as down-aileron (to increase drag on the side he wished to turn). So they improved the turning qualities by increasing rudder area.

Soon SUMPA was flying over 650 yards.

Only eight days after SUMPA’s first fight, the de Havilland team at Hatfield flew Puffin for the first time. During the long months of design and construction the Hatfield club had been working in great secrecy; yet each team was aware of the other’s efforts, and each was competing for the prize.

Despite the independent approach of the teams, the same decisions were reached on the most basic points. Puffin has the same slender wings that distinguish SUMPA.

Structure is extremely light. For example

the fuselage (less pilot structure, wheels etc.) weighs less than nine pounds, and the tailplane (less elevators) less than five pounds. Full net weight is 118 pounds. Materials used in construction are balsa and spruce, with magnesium for the pilot’s and transmission support structure.

De Havilland may not officially be in charge of the Puffin program, but their association with it has undoubtedly led to the support other industries have given. Dunlop designed, developed and donated the complete transmission system, gear-boxes, wheels and special tires. Imperial Chemical Industries donated and gave technical advice on a special lightweight nylon sheeting that covers the complete airplane. Balsa was specially graded and supplied free. And amid a long list of other industrial participants in the U.K.Atomic Energy Authority for advise on the dispersion of static electricity.

Puffin’s flight development is proceeding with more secrecy than many a military program I have known. First flights were by test pilot J.H. Phillips of de Havilland Aircraft, later ones by test pilot J.L. Barnes of de Havilland Engines. Finally in February 1962 came John Wimpenny, Assistant Chief Designer of de Havilland Aircraft.

The important point about John Wimpenny is that he is not a pilot. If experienced pilots found difficulty controlling man-powered types, you would expect non-pilots to find it impossible. Yet, probably because of difference in response and type of controls, pilots start with few advantages. Soon Wimpenny was flying Puffin as easily as anyone.

He flew 993 yards on 2 May 1962.

Rumors have since then been rife that a small engine was installed on Puffin to allow the pilot to take his mind off power-production and concentrate on turning. The trials were successfully completed and the pilot is now said to be practicing without the use of the engine.

I heard the view expressed by a member of one of the teams that the Kremer prize will not be won for at least another year. Though I do not personally agree with this, it would certainly be advantageous to the entrants of the third man-powered airplane on the list—the machine from Southend (not to be confused with Southampton). This is a two-place design by a group headed by Andrew Drescher. It is only now reaching completion.

Southend’s machine employs constructional techniques similar to the other two but features a balsa propeller of tractor type mounted on a pylon above the cockpit. The crew of two sit side-by-side in a reclining position supported by seats set in an aluminum alloy frame. The wing is larger than both SUMPA’s and Puffin’s but has a section nearly the same as the former. And each wing has three six-foot ailerons so that any difficulty in turning can be ironed out by experimenting with a combination of these.

Andrew Drescher is quietly confident that he will have all the power he needs. The airplane is expected to weigh only marginally more than the others, 140 pounds empty, yet will have about double the power. Pilot will be Barry Stracy, a Britannia first officer with British United Airways. Crew will be Carl Barton, the champion cyclist. This airplane has a good chance of winning the Kremer prize, but even if it fails, it will still be the first man-powered two-place machine in the world.

This is the line-up in the man-powered contest. But the triangular race is only starting and the full story cannot be told until it is won.

Thanks for making it to the end. See you in the next one!

Discover more from Buffalo Air-Park

Subscribe to get the latest posts sent to your email.